- その他のフルークグループ:

- Fluke

- Fluke Biomedical

- Fluke Networks

- Fluke Process Instruments

Fluke Calibration Software: Into the Future

We’re celebrating the 30-year anniversary of MET/CAL Calibration Management Software with a series of blogs, articles and social posts that call out milestones and interesting points of view from some of the Fluke Calibration team.

In celebrating MET/CAL, we’re also celebrating the thousands of MET/CAL users who have interacted with the application, and Fluke Calibration, over the past 30 years. Some of you have been with us since MET/CAL ran on DOS! Your willingness to ask questions, experiment, and offer your opinions (often strongly stated) have helped to shape MET/CAL as it is today, as well as the projects we are working on for the future.

Overview

In this post we summarize the discussions during the three virtual software user groups we hosted in September 2020. These meetings replaced the in-person user group that we typically hold at NCSLI, which of course was cancelled this year. Many of you attended at least one of these meetings, but if you missed them you can find the full recordings, including the topics outlined in this post plus question-and-answer sessions throughout, on the Fluke Calibration website.

As a convenience we are including the approximate times stamps for each major segment, in case you want to fast forward to a topic of particular interest.

Fluke Calibration Software team: who are we?

The Fluke Calibration Software team is a group of 30 calibration enthusiasts who help over 1000 metrology labs stay up and running with our software. Our team by the numbers includes:

- 23 engineers, software designers and metrologists

- 7 dedicated customer support, implementation and training professionals

- 1000+ strong community of organizations using Fluke Calibration software in their labs

Our team’s dual missions:

- Providing outstanding tools and support of current portfolio products to enable critical operations for our customers

- Pioneering software innovation to spur forward progress in the field of measurement science

User Group speakers included:

- Colin Walker, Sr. Business Unit Manager, Software

- Mike Brown, Software Metrologist, Product Owner: Cubyt

- Andrew Chapman, Software Sales Account Manager

- Chad Dodds, Manager, Technical Support and Training

- Michael Johnston, Product owner MET/CAL, MET/TEAM, MET/CONNECT, COMPASS

- Aravind Raghunath, Innovation Manager, Product Planner

- Bill Spath, Technical Specialist

User Group Meeting 1 of 3: Software Roadmaps and Release Schedule

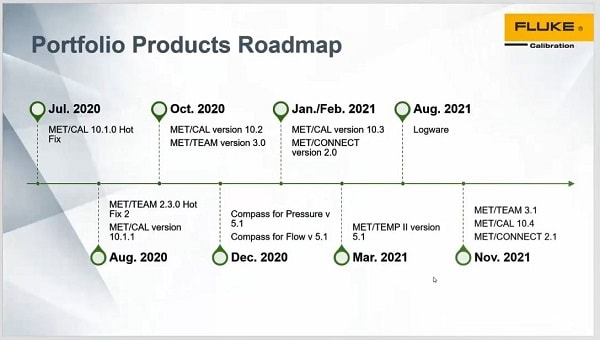

Why share our plans? (10:02). The first meeting aimed to set expectations with the user community about what our plans are. We do this because you may need to plan ahead to obtain resources in your organization for things like a MET/CAL software upgrade, so it’s important for you to know approximately what is going to happen and when. We reviewed the product roadmap from July 2020 through November 2021. It includes new releases of MET/CAL, MET/TEAM and COMPASS for Pressure in 2020; more new releases through 2021; and new releases of LogWare and MET/TEMP in 2021. We also provided a sneak preview of some of the key features coming in the 2020 releases of MET/TEAM v3.0.0 and MET/CAL v10.2.

MET/CAL v10.2 summary of features

- Embedded browser update

- Editor update to VS2015 shell

- Instrument configuration screen upgrades

- Bug fixes

- FSCs for 4180/4181 and 5322A

- FSC for Clarke-Hess 6000A

- Improved logging and easy “collect logs” feature

- New updated logo/splash screen to celebrate 30th anniversary

MET/TEAM 3.0 summary of features

- Data check improvements

- API (one-way for initial release)

- Speed improvements

- Saving work orders tested as much as 1000% improvement

- Adding standards tested as much as 100% improvement in large databasaes

- Manual template dynamic limits calculations

- Bug fixes

Engineering commitment (16:39). During this meeting we communicated the engineering commitment for active software products, including MET/CAL, MET/TEAM, MET/CONNECT, Cubyt, COMPASS, MET/TEMP II and LogWare. This commitment includes:

- Minimum 1 release per year

- New features based on user feedback and requests

- Current support for Microsoft Windows and browser

- Critical issue releases.

Software end of life (21:13). We will provide a four-year window to manage end-of-life changes so there will be no surprises.

Cubyt (26:59). What is Cubyt and why is it revolutionary?

- Cubyt is a central online community for metrologists, where they can access and share metrology content (for example, procedures and data sheets).

- Over time, Cubyt will become a repository of every instrument on earth that can be calibrated.

- Cubyt will provide instant access to cal sheets with test points and tolerances.

- The community is initially powered by the Cubyt team of metrologists, who are loading instruments, specs and methods.

- In future the community will include community ratings, reviews, tips, and instructions.

Cubyt is free to use. The team sends out updates every other week and hosts a monthly user group meeting. You can sign up for Cubyt here.

MET/CONNECT (49:21). While MET/TEAM is a complete application for managing calibration assets, MET/CONNECT Calibration Integration Software is designed for labs that already have asset management software and want to connect it to MET/CAL, or who simply want to automate data exports as a .csv file.

User Group Meeting 2 of 3: MET/CAL – Beyond Electrical Calibration

Automated procedures (06:23). We began the meeting with a discussion of automated procedures, including:

- Fully automated (“set it and forget it”)

- Closed loop (devices controlled – operator intervention required).

- Semi- automated (some devices controlled but not all of them – operator intervention required.)

- Technician assist (no devices controlled / Instructions and data collection).

Benefits of automation:

- Reduced calibration time, especially when using fully automated procedures

- Consistency between technicians; calibrations are performed the same way every time, no matter who is performing them

- Step-by-step instructions, prompts, execution, so even lesser skilled operators know what to do

- Uniform data storage so you can use existing reports

- Automatic calculations (Tolerance/TUR, measurement uncertainty, guardbanding/claims of compliance) save time and effort

Procedure example/automated steps review (09:34). We showed a procedure for a 5520A Multi-Product Calibrator, focusing on the automated steps inside a single line of Function Select Code (FSC). FSCs are the way we describe a high-level MET/CAL command; for example, to display a message or show a picture in a procedure. FSCs come with options and parameters that you can configure to get the results you want. One line of FSC code can replace perhaps 50+ lines of hand-written code.

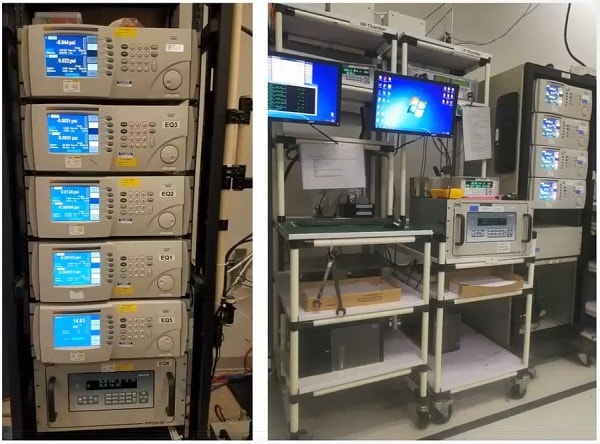

Advanced MET/CAL (14:26). In this segment we showed “extreme” examples of ways we are using MET/CAL at Fluke:

- Infrared blackbody calibration to calibrate the Fluke 4180/4181 Precision Infrared Calibrators

- Pressure calibration chamber to characterize pressure gauges (pictured above)

- Stepper motor control/curve fitting using the Math FSC, showing how MET/CAL can control any DUT that has IEEE, RS-232, or USB connections

- Externally-driven procedure that pulls information about tolerances, test points and more in a spreadsheet and the Library FSC is used to control the DUT. This approach can be beneficial if you need to add or remove a test point or change something after an assessment because you don’t have to open individual procedures.

Manual calibration with MET/CAL (24:50). In this segment we provided examples of technician-assisted procedures, where the actual calibration is not automated but benefits such as results collection, measurement uncertainty calculations and standard reports can be realized. Examples included calibration of a simple micrometer and a torque wrench.

User Group Meeting 3 of 3: Making the Most of MET/TEAM in Your Lab

This session began with a replay of the coming year’s software roadmap. Then we focused on MET/TEAM and provided answers to common questions as well as tips and tricks to make using MET/TEAM easier.

- Migrating your existing data from MET/TRACK or another program

- Why it’s important to clean your data before migrating

- We have created a video about how to review migrated MET/TRACK data in MET/TEAM. You can watch it here.

- We have an article to answer the question, where does my MET/TRACK data go in MET/TEAM? Read it here.

- System configuration: how to set up to make it work

- Setting user permissions

- Finding data

- Reporting

How to get software help

- Fluke Calibration software applications have built-in help

- Website: https://support.flukecal.com/ (KB, articles, community forum, send questions to Tech Support

- Email: softwaresupport@flukecal.com

- Phone: 1.800.825.7411 (toll free) or 1.425.446.6476

- Get software price quotes or a sales consultation

Related products

MET/CAL Calibration Management Software

MET/TEAM Test Equipment Asset Management Software

MET/CONNECT Calibration Integration Software

MET/TEMP II Temperature Calibration Software

9934 LogWare Temperature Calibration Software

- ホーム

- 製品

- ご購入について

- ニュース

- トレーニングとイベント

- カタログ・資料

- サービスとサポート

- フルーク・キャリブレーション